|

Input Power

|

- AC 208-240V Single Phase, 50/60 Hz

- 1.5 KW (for glove box); 2.5 KW ( for PVD coaters)

- Total: 4.0 KW

|

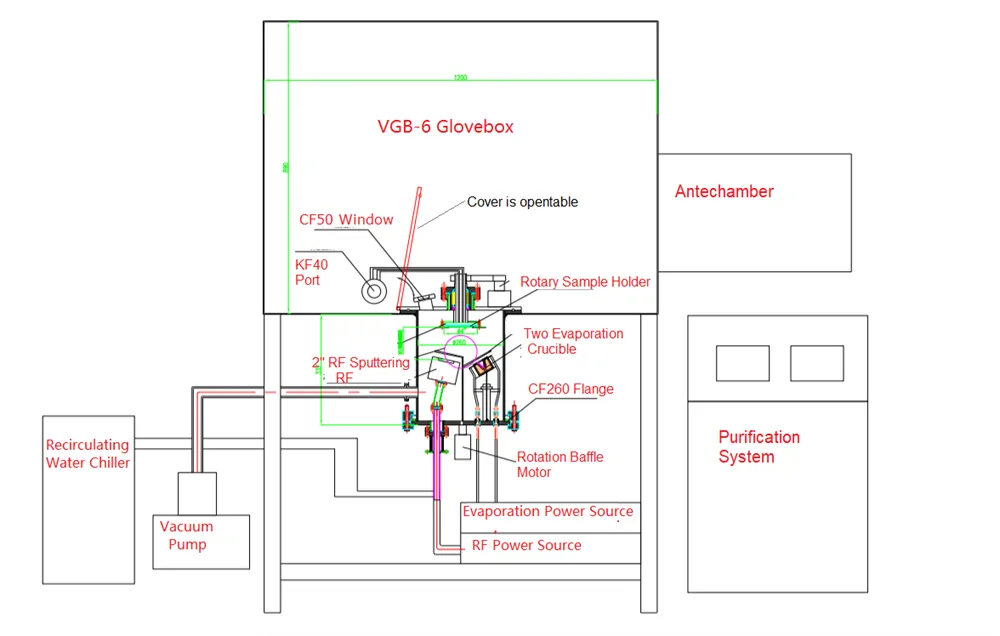

Glove-Box

|

- Chamber dimension: 1200 mm L x 740 mm W x 900 mm H

- The gas purification station is included to ensure O2 & H2O less than 1ppm) in the glove box.

- Case Material: Stainless steel 304 with 3 mm thickness

- Chamber dimension: 1200 mm L x 740 mm W x 900 mm H

- Openable front window panel (tempered glass, 8 mm thick) for easy device loading

- Please Click Picture left for detail specification

|

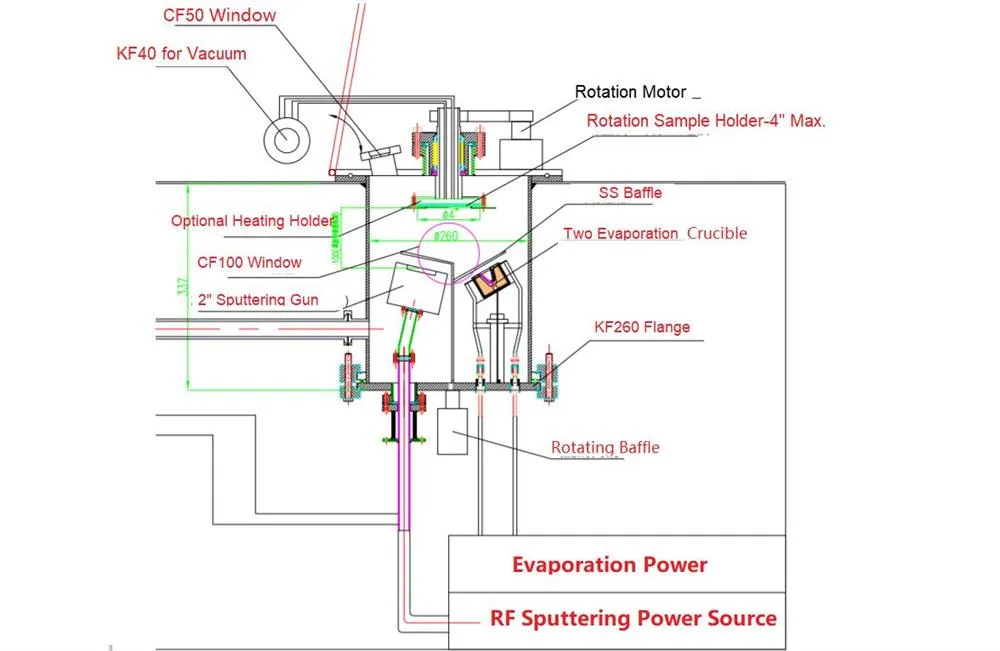

Vacuum Chamber and sample holder

|

- The vacuum chamber is made of SS304 and recessed in the bottom of the glovebox

- The top flange is the hinged type and operable manually

- Two quartz windows are installed in the chamber fro observation.

- Plasma sputtering head and two evaporation heater are installed on the bottom of the chamber.

- One rotary sample holder is built-in the top of the flange which can hold max. 4" sample

- Rotating speed: 5 rpm

- One rotary shutter is built-in the bottom of the flange, which will cover two coating source during one source working to avoid the cross-contamination.

|

RF Plasma Generator

& Sputtering Head

( click the picture to see detailed specs)

|

- One 13.5 MHz, 300 W RF Generator with automatic matching function is installed in the outside glovebox and connected to 2" sputtering head (click picture 1 to see detailed specs).

- One 2" Magnetron Sputtering Heads with water cooling jackets are inserted into the vacuum chamber from the bottom of the glovebox. (click picture 2 to see detailed specs).

- One 16 L/min digitally controlled recirculation water chiller is included for cooling magnetron sputtering heads (click the picture 3 to see detailed specs).

- The RF sputtering head can despite either insulation material or conductive material

- Pic.1 Pic. 2 Pic.3

|

Thermal Evaporation

|

- Two tungsten coil heaters with two B type of thermocouples and Alumina crucibles are built at the bottom of the vacuum chamber ( See Pic. 1)

- One digital temperature controller with 30 programmable segments and /- 1 ºC accuracy to control the heater (PIC. 2)

- One power switch is installed to change heating from one crucible to another by the same temperature controller

- Working temperature: 200ºC - 1700ºC

- Recommend Heating rate: 0.3 ºC/s (RT-1200 ºC) and 15 ºC/s (1200ºC - 1700 ºC)

- Four alumina crucibles (up to 1700 ºC) and two tungsten coil heaters are included. Please refer to the Optional section for ordering spare parts.

- Pic. 2

|

|

Vacuum Pump

|

- The KF25 vacuum port is installed to connect to a vacuum pump

- The highest vacuum may reach <4.0E-6 Torr by pumping overnight with optional Turbopump

- is included for vacuum up to 1.0E-6 TorPic.1

- A vacuum pump is optional. Please click Pic. 2 or 3 to order ( 10-2 torr) or turbopump ( 10-5 torr)

- Pic. 1 Pic. 2 Pic. 3

|

|

In-Situ Film Thickness Monitor

(Optional)

|

- In-situ high precision thickness monitor for the thin film deposition process is recommended. It is based on the principle that the mass of a deposited film on a quartz crystal can be measured by monitoring the change in crystal’s oscillating frequency.

- Thickness accuracy: 0.1 Å

- Please click the picture left to see detailed specifications.

|

|

Net Weight

|

~800lbs |

|

Warranty

|

One-year limited warranty (Consumable parts such as heating elements, processing tubes

and o-rings are not covered by the warranty) |

|

Compliance

|

- CE Certified

- NRTL certification (UL61010) or CSA certification is available upon request at extra cost.

|

|

Operation Instructions

|

|